Induction IE3 Efficiency Motor

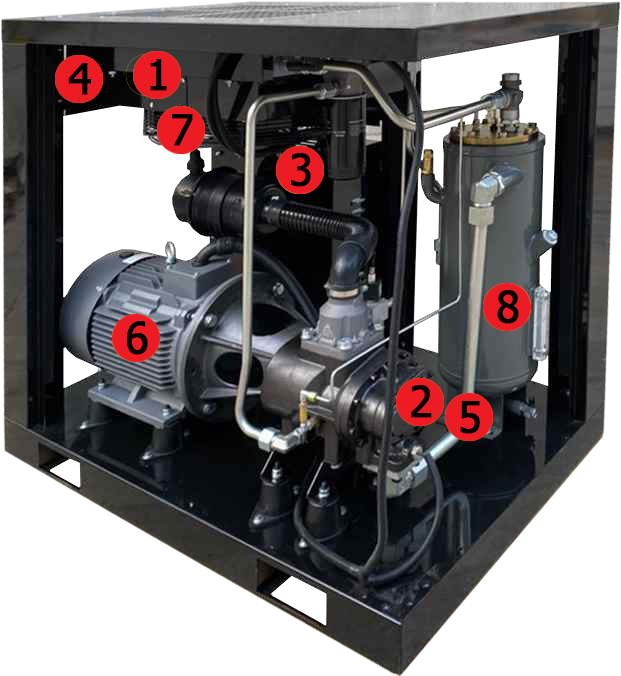

(1) Color coded on/off buttons

(2) Fault indication and reset function

(1) High Efficiency Radial Fan

(2) No Thermostat Fan Start/Stops on

(1) Low maintenance cost

(2) Increased life of bearing

(1) No Rubber Hoses

(2) Less maintenance cost

Less Oil Carryove

(1) Specially designed for compressor application

(2) Safety protections like Single Phasing "Motor Overload, Etc.

Oversized Coolers designed for High Ambient Temperatures upto 50° C

WhatsApp us